More Than 90 Years of Experience

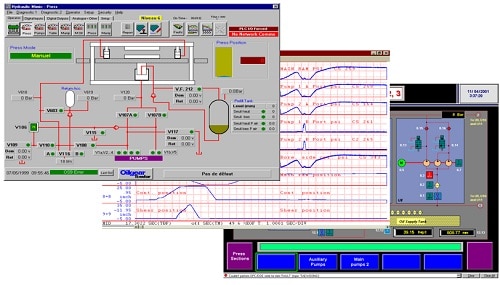

We’re known for designing, installing and commissioning complex hydraulic control systems. In fact, Oilgear is a world leader in it. We work with a variety of industries, including forging, extrusion, wood and sheet molded composites. And our electrical and hydraulic engineers work side by side to deliver the precision control and user interface you require.