Helping you fully understand your system.

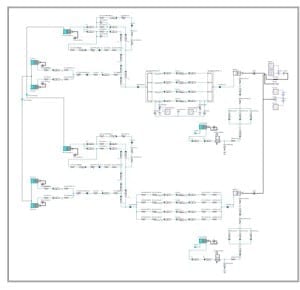

Utilizing industry-standard SimulationX software, as well as proprietary Oilgear code, Oilgear excels at leveraging multi-physics simulation to help you better understand your complex system.

For more than three decades starting in the late 1970s, Oilgear wrote its own proprietary code for simulating complex and dynamic physical events. Oilgear’s early multi-physics simulations included hydraulic, mechanical, and electrical elements and went so far as to properly capture fluid transients and thermal effects.

In 2012, Oilgear transitioned to using SimulationX software. SimulationX is the the gold standard for modeling highly dynamic, real-world phenomena and has extensive libraries of proven building-blocks for creating simulations.

With SimulationX, Oilgear can generate extremely detailed models of our proprietary products, and then encode them into a “black box” that we can offer to our customers. This ensures that Oilgear customers have the most accurate models of our products within their system-level models.

A ONE-STOP-SHOP FOR ANALYSIS

Oilgear offers a complete suite of hydraulic product and system analysis services, making Oilgear a one-stop-shop for your analysis needs.

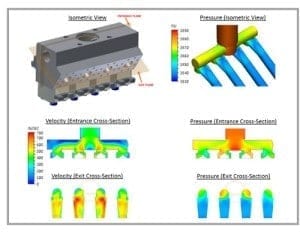

Under one roof, Oilgear offers system simulation, computational fluid dynamics (CFD), finite element analysis (FEA), and some of the most dynamic hydraulic testing capability in the world. This enables Oilgear to quickly build real-world results its software simulations, ensuring that the computer model of the system is as accurate as possible.

Any time there is a critical need to understand a complex physical event that includes hydraulic, mechanical, and/or electrical elements, it’s prudent to develop a simulation.

Some of the simulation analysis projects that Oilgear has recently participated in include:

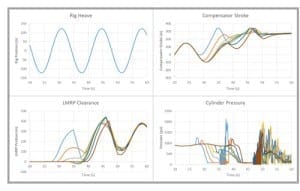

Offshore Emergency Disconnect Sequence (EDS) riser recoil analysis and product development

Water-hammer (i.e. pressure spike) mitigation and product development

Offshore motion compensation system design analysis

Hydraulic press (i.e. forging, extrusion, wood) control system analysis

Subsea pressure control system simulation and troubleshooting

Safety shutdown reaction timing

Gas and liquid hose burst simulation and product development

Chemical injection system hydro-mechanical analysis

Water-jet cutting pressure variation analysis and product development

Subsea blowout preventer (BOP) control analysis and product development