Oilgear to Exhibit at MINEXPO 2024 in Las Vegas

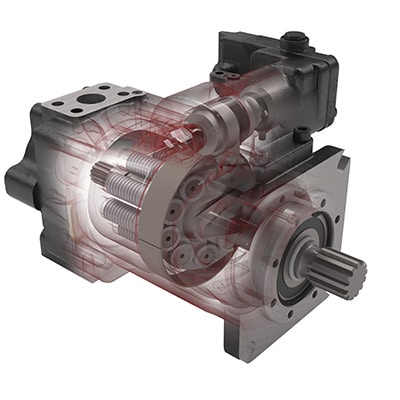

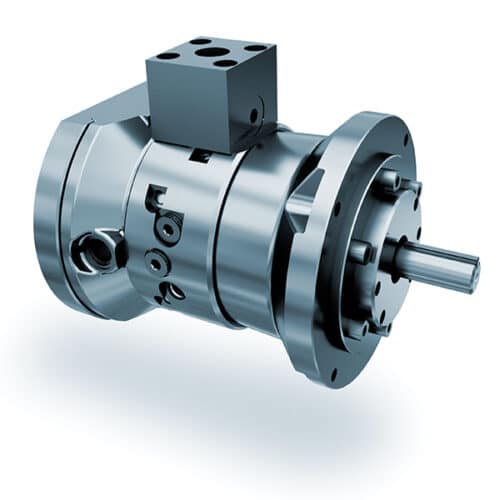

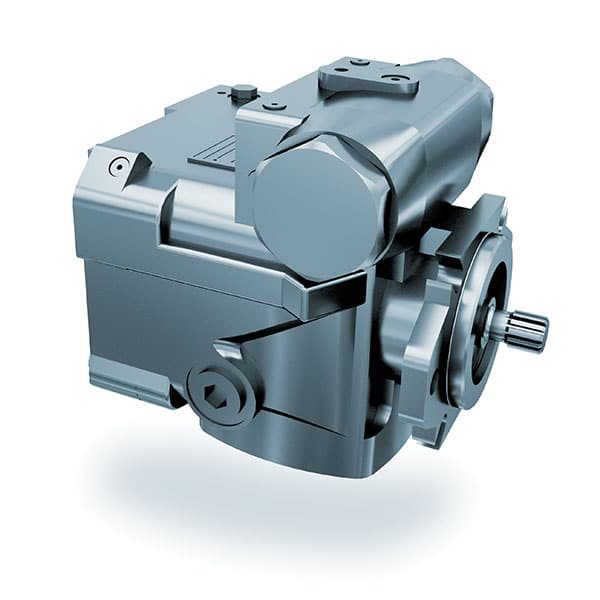

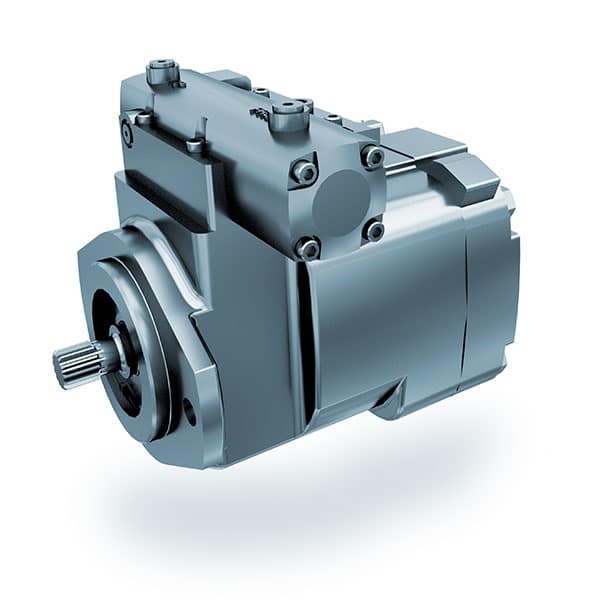

Visit Us at MINEXpo 2024 We are happy to announce that Oilgear, in collaboration with Texas Hydraulics and Hydromotion, will exhibit at MINEXpo 2024 in Las Vegas. Join us at booth 10367 from September 24-26 to explore our latest advancements and discover how we can be the best industry partner for any mining application. Together, […]