The Manifold Experts

Oilgear has built a reputation on superior engineering and unbeatable reliability. As a result, our modular and integrated manifold systems are used worldwide for a wide variety of applications.

Oilgear has built a reputation on superior engineering and unbeatable reliability. As a result, our modular and integrated manifold systems are used worldwide for a wide variety of applications.

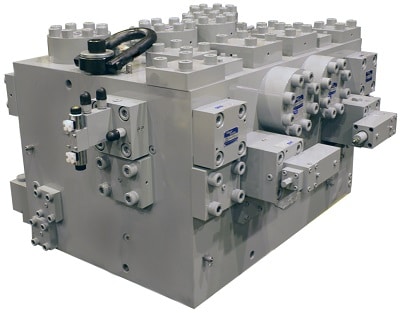

With our understanding of manifold design and manufacturing, we’ve been able to innovate essential advantages for our systems—like reduced size, weight and cost. Known for their quality and reliability, Oilgear systems provide a clean, leak-free solution for your most challenging control system problems. Our systems use the latest available software modeling techniques. That means you can trust your manifold will exceed your expectations.

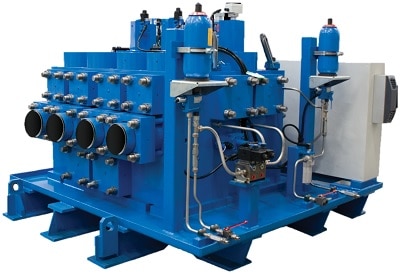

We have manufacturing facilities in the United States, Europe and China, so we can supply manifolds anywhere in the world. We provide a range of sizes from small single-function units to manifolds weighing up to 50 tons. All manifolds are assembled and tested in Oilgear facilities.

All manifold sizes are available in pressure ranges from 500 psi (35 bar) to 15,000 psi (1000 bar).

The Oilgear manifold is a hydraulic component. It regulates the fluid flow between pumps, actuators and other system components. It allows the operator to control the quantity of fluid flows between components of hydraulic machines—much like a switchboard in an electrical circuit.

Our modular and integrated manifolds simplify maintenance and reduce fluid leakage. Modular-type manifolds can be mounted horizontally or vertically to meet circuit needs.

Oilgear makes manifold blocks for high-powered, large industrial applications. These can weigh more than 40 tons and can handle water or mineral oil. Oilgear also creates compact manifolds for ROVs, subsea and offshore applications. These can be made out of stainless steel, aluminum or titanium.

For more demanding applications, our high-strength, steel-integrated manifolds can withstand extreme operation pressure and allow higher throughput rates with minimal pressure drops.

With years of design and manufacturing experience under our belts, we’ve created many advantages for our manifolds—including reduced size, weight and cost. Our high-quality systems provide cleaner, leak-free and more reliable solutions to our customers’ most challenging control system problems.

We’re pleased to offer the following signature, engineered solutions to our customers: