Solutions for Complete Control

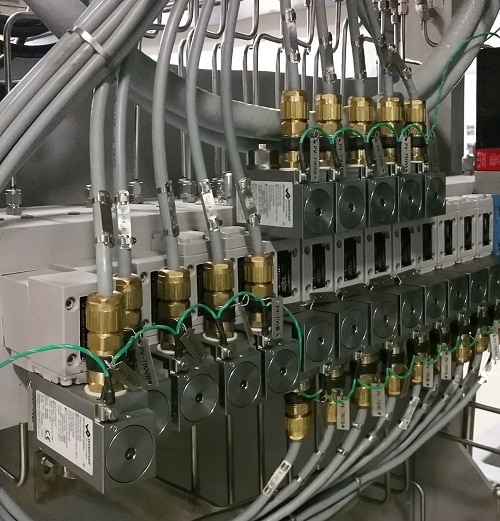

Oilgear experts have been engineering and commissioning electrical control systems for nearly a century. That experience helps us supply highly engineered hydraulic systems to our customers across the world.

Oilgear experts have been engineering and commissioning electrical control systems for nearly a century. That experience helps us supply highly engineered hydraulic systems to our customers across the world.

Since 1921, Oilgear has been supplying electrical control systems to accompany our hydraulic products and systems. They’re used across the world for a diverse range of applications, including:

Oilgear works with leading names in control software and software tools to make solutions for your operations. We utilize a variety of software to make your system successful, including:

Oilgear consistently partners with customers with demanding applications. We have an extensive knowledge of codes and certifying agencies. We conform to a number of them, including: